solar, low-cost building programs. Remaining problems are:

a.) the necessity to incorporate additional thermal storage to limit swings, and b.) integration of auxiliary heating systems into the building with minimal redundant construction.

Plenum floors, in use here since WWII, have gained acceptance as highly economical systems for thoroughly integrating the storage and distribution requirements of passive design. My first plenum floor residence (1975) used industrial roof decking to form the "mini -ducts" for air distribution and other similar residences have followed. The charging of the slab from below as well as from above increases the storage efficiency of the masonry slab allowing reduction in the amount of additional storage usually necessary in such buildings Twenty-one such systems have been completed, and additional projects are under construction'. The lay-outs have ranged from the simplest rectangular forms to complex angled schemes with elevational transitions, proving the system to be most adaptable.

Construction details and performance results are discussed. Costs are compared in a general fashion to other plenum floors and conventional systems. .....

In 1936 after ten years without a single commission, Frank Lloyd Wright produced the first Usonia residence, the Jacobs house, and the Johnson's Wax building. Both structures served to introduce this country to the benefits of radiant slab construction. Wright borrowed this trick from the Koreans, who for centuries had been passing hot flue gases under their floors.

He was also aware of the Romans' work in this arena. For some reason that is unclear to me, Wright dubbed this "natural" heating distribution systems "gravity heat." Radiant slabs continued to be incorporated in Wright's work and were soon adopted by others. However, Wright's systems first used steam and later water, which finally became the generic standard.

These liquid radiant slabs did have many advantages over traditional convective systems- including baseboard. They provided minimum stratification from floor to ceiling with temperature ranges of less than 5 degrees F when 15 degrees F is not uncommon with conventional systems. Additional advantages of this system are that it places the heat a~ your feet, which is indeed pleasant, and does not intrude on the room with registers, baseboard units, or "radiators." These benefits combined with low-cost, slab-on-grade construction encouraged wide-spread application of the system, culminating in the post war period with Levittown."

Of course there were drawbacks.

1. Failures of these liquid systems abounded with rupturing of the pipes caused by corrosion by concrete alkalines and incompatible coefficients of expansion. Construction of a liquid radiant slab that avoids these failures is rather costly.

2. No opportunity to condition the air for humidity or dust control.

3. No allowance for space cooling.

4. Extreme lags in slab response to ambient conditions, aggravated by good passive design.

Obviously one wants to design a system that retains or features all the good points of a liquid slab and eliminates or minimizes the draw-backs. The air floor or radiant plenum floor succeeds rather well.

2. SYSTEM SOLUTION

The essence of the solution is to substitute air for the liquid and voids for the pipe. Registers must be provided to allow air movement through the voids.

The system works as follows:

1. Because the system no longer contains liquid there are no problems of potential leaks and construction costs are sharply decreased.

2. Thermal lags of over four hours are cut to as little as thirty minutes. Approximately half the heat is delivered to the space convectively and half radiantly.

3. Circulating the room air through the mechanical equipment permits control of dust and humidity.

4. Earth '.contact" allows for a cooling effect similar to that provided by now popular cool or earth tubes, and

5. Solar gains not stored in the direct-gain slab-on-grade construction that become stratified convective gains can be collected from the ceilings with a "fan only" mode of operation and used to charge the slab from below. Both surfaces of the slab now work where as only the top had previously.

3. CONSTRUCTION

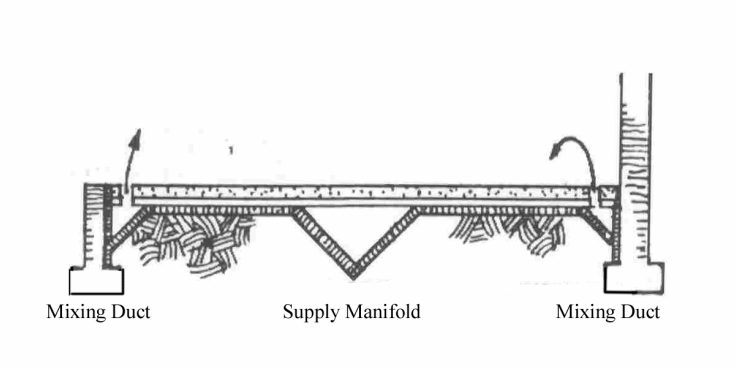

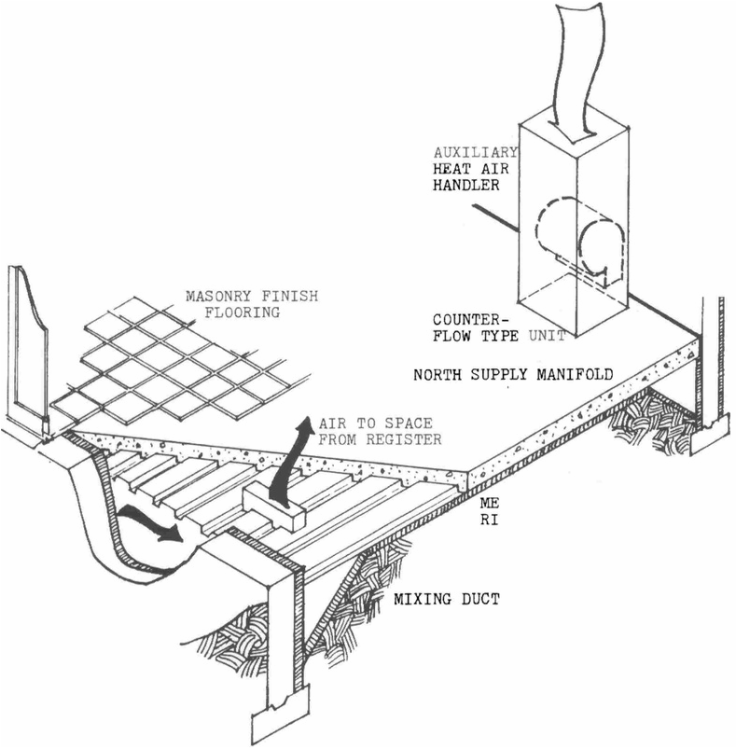

Investigation of concrete block floors with respect to material and labor costs proved disheartening. Industrial metal roof decking provided the answer. In simplest form the system is built as follows. For a simple east/west rectangular plan with south glazing (a common enough plan form) the grade is first prepared for a concrete slab in the usual fashion. Rigid foam insulation is carefully laid down over the final layer of screeded sand. I most often use two-inch thick bead-board but polyisocyanurate foam board is recommended for those concerned with toxic combustion products. Most sources advise against placing any insulation under a direct gain slab, but because the delta-T is now substantially increased in this system, insulation is required in order to prevent large heat losses from occurring.

Running east/west along the inside of the north frost wall install a vertical foam board and, as you approach this edge, excavate and turn down the horizontal foam boards at approximately 45 degrees to make a "vee" trench. This manifold runs continuously along the north frost wall and is proportioned like any proper supply duct tree. Along the south frost wall install the insulation in a like manner except the "vee" trench mixing duct need only be eight inches across the top. The steel decking is merely a form and thus is the cheapest grade I II inch type "B'. roof deck, 22 gage, painted finish. It is laid in two lengths lap-spliced in the middle allowing them to be spread tightly against and slightly into the vertical perimeter foam insulation and then locked with either tack welds, pop-rivets, or self-tapping duct screws. The concrete is poured over the decking to a thickness of about six inches to the bottom of the rib. The slab is reinforced with 6'.x 6"/10-10 temperature welded wire mesh and the necessary re-bars to span the manifolds. 1 1/2 inch flats on the bottom of the decking six inches on center bearing on 25 p.s.i. foam provides 900 pounds per square foot safe total loading. Sinuous decking would probably sink into the foam.

4. FINISH AND OPERATION

The slab can be finished with masonry (tile, stone, brick, terrazzo), or treated a la Wright with scored pattern, color, sealer with a wax finish. I have seen one of Wright's floors almost forty years later, and it looked brand new, like burnished leather. One would easily mistake it for some synthetic resilient flooring. My own efforts in this direction have been acceptable but less stunning than Wright's.

Another option is carpeting or wood flooring. This insulation will reduce the radiant delivery fraction and increase reliance on the convective component.

During the solar gain periods, as with any hybrid system, the auxiliary heat blower fan should remain OR. This switching can be performed manually or by automatic thermostatic sensors and solenoids. It is not necessary to operate the fan in order to recover the heat when needed because radiant delivery is usually sufficient. The auxiliary heating system can also be operated manually or by the customary thermostat.

5. VARIATIONS

Because the plenum floor is a distribution system, it can be coupled with any back-up system desired as long as that equipment produces hot air rather than hot water (although a fin-coil may be used here as a boiler adapter). I currently have in operation systems that are coupled to oil-fired furnaces, bottled gas units, "street" gas furnaces, wood/coal furnaces, air-source and water-source heat pumps, and even straight electric resistance furnaces. The system works well with either low temperature "trickle" feed sources or rapidly charging high temperature sources as with a Russian fireplace.

6. CONCLUSIONS

In the immediate future the plenum radiant floor system clearly will be used for a great deal of commercial and residential passive solar construction. It eliminates the conventional heat distribution system and replaces conventional ductwork with permanent materials not subject to rust or deterioration over time. Additional costs over straight slab-on-grade construction are the metal decking and foam insulation board. It is my experience that these items about wash even to the cost of the replaced ductwork. I have also found that a square foot of decking costs less than one of concrete block, concrete prestressed decking, or Airfloor Company's patented forms. The labor to install the all-decking system is certainly less and the least amount of poured work is called for.

Performance in terms of comfort is excellent. comfort is insured by working with solar gains and radiant heat fluxes instead of with traditional convective fluxes. The convective gains produced are placed most effectively and are recovered quickly from overhead spaces.

The convective flows are low temperature/low velocity currents that provide the most comfortable "climate" possible. This system has the ability to utilize for storage mass in areas other than those closely coupled to the solar aperture. In addition the system retains the ability to heat spaces remote from the solar aperture.

7. REFERENCES

(1) M.S.E.S. Newsletter' April, 1981. Solar Home Journal, Scott Lewis.

(2) M.S.E.S. Newsletter June, 1981 Radiant Slab Heat Recovery, Scott Lewis.

(3) Northeast Solar Energy Center Technical Field Support Program, Radiant slab

Heat Recovery, Scott Lewis. August, 1981

(4) Solar Age. May,1982. RadiantFloors, Scott Lewis

Note: This article refers to the thickness of concrete floor as six inches. I have since determined that the optimum thickness is 4 1/2 inches. This is measured from the bottom of the rib to the top of the slab. If a stone slab finish is required, than the concrete thickness should be 3 1/2" - with 2" above the top of the decking and 2" from the top of the slab to the top of the stone. If a tile finish is required, the slab should be 4" thick with an additional 3/4" to the top of the tile.

RSS Feed

RSS Feed